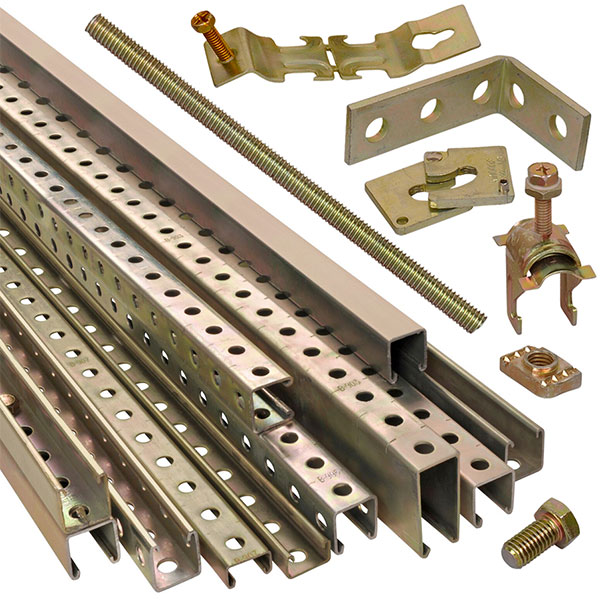

Kindorf Metal Framing

Designed for the maximum number of support and framing applications with the minimum amount of labor and materials.

Modularity saves labor and inventory

ABB Installation Products’ Kindorf® metal framing system is a modular, versatile and labor-saving solution for building supports, hangers and frameworks across electrical, mechanical and industrial applications. This modular design not only simplifies installation and reduces material waste but also provides long-term flexibility for modifications, expansions or repairs.

Key benefits

Made in Athens, Tennessee, Kindorf provides standardized 1½” channel dimensions, precision hole spacing and wide range of fittings, allowing components to connect in virtually any configuration – side-by-side, back-to-back or at angles – without field welding or extensive cutting.

- Superior corrosion protection – Galv-Krom® finish protects all threaded components, channel and fittings

- Strength – Although slightly smaller, 1½” channel supports the same weight as 15⁄8 ” channel

- Minimal waste – Scribe marks and hole positioning provide easy cutting and ensures balanced support on every piece

Part of the ABB EcoSolutions™ portfolio

Offering customers and partners full transparency on the environmental impact of our products and empowering them to make sustainable decisions. Kindorf strut channels meet ABB's circularity criteria in each dimension of the product life cycle and have externally-verified Environmental Product Declarations.

Kindorf Channels EcoSolutions product profile

Kindorf Clamps EcoSolutions product profile

Applications

- Support & framing

- Pipework

- Trunking

- Ducting

- Cable tray

- Light fittings

- Conduit & cables

- Suspended ceilings

Technical data

Kindorf metal framing system is a heavy-gauge structural-quality steel channel, cold-formed into a "U" shape with a continuous open slot and 1½” modular dimension. The design features pre-punched holes and scribe marks to simplify field cutting and installation, while ensuring all parts and accessories fit together to reduce waste.