HD5

HD5 is a three-position device developed to meet most of the demands of the Food and Beverage industry.

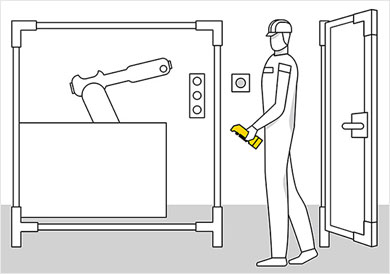

A three-position device is used to allow limited movement of the machine when the operator is in the dangerous area, for example during troubleshooting, test running and programming. The operator pushes the larger black button to a middle position to allow movement. In case of danger, the operator will either release the button or squeeze it to its bottom position and the machine will stop.

The housing of the HD5 is made of PPh, that not only is approved for contact with foodstuff, but also resists the most commonly used chemicals during cleaning in the Food and Beverage industry. Designed without sharp edges, there is no place where dirt and bacteria can accumulate. The construction of the HD5 prevents condensation inside the product when subjected to temperature changes in a wet environment. The PPh used is fiberglass reinforced to prevent breakage and minimize risk of small broken bits falling in the product.

Features and benefits

Optimum interface

- Red/green LEDs available to give visual status to operators

- Auxiliary buttons for additional functions

- Integrated emergency stop and flashlight available

- Fiberglass Reinforced Plastic minimizes breakage and anti-condensation membrane prevents moisture from building up inside

Continuous operation

- Designed to meet the demands of Food and Beverage applications

- Made of PPh that is approved for contact with foodstuff and that resists the most commonly used chemicals during cleaning

- Allows the operators to safely inspect the manufacturing process without completely stopping the machine

Safety and protection

- No sharp edges or places where dirt and bacteria can be accumulated.

- Highest Level of Safety Category 4/Ple

- Home position sensor detects HD5 in its holster

Application

Used in applications where an operator is in the hazardous area and only limited movement of the machine is allowed. This allows the operator to be in full control and safely inspect a manufacturing process without completely stopping the machine. Examples are robotic cells and automated equipment bypassing, machine adjustments and teach or maintenance processes.